![[Lone Sentry: WWII Tactical and Technical Trends]](../../pics/sentry120x69.jpg)

![[Lone Sentry: Photographs, Documents and Research on World War II]](../../pics/lonesentrylogo.jpg)

|

The following U.S. military report on the Japanese 47-mm antitank gun was printed

in Tactical and Technical Trends,

No. 43, January 27, 1944.

[DISCLAIMER: The following text is taken from the U.S. War Department

publication Tactical and Technical Trends. As with all wartime

intelligence information, data may be incomplete or inaccurate. No

attempt has been made to update or correct the text. Any views or

opinions expressed do not necessarily represent those of the website.]

|

|

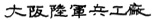

JAPANESE 47-MM AT GUN*

Reports of the enemy's defense of Guadalcanal included information concerning the employment and effectiveness of the Japanese 47-mm antitank gun (see Tactical and Technical Trends, No. 19, p. 5). Detailed information about this gun has now become available and it is presented herewith. a. Characteristics

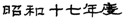

Marking (with translations) found on gun

Marking (with translations) found on rubber tires

The tube is of built-up construction. It consists of a long barrel with a heavy reinforcing muzzle band, common to Japanese pieces. The tube is sweated into a jacket which in turn is attached to the breechring. The breechring is machined to receive the tube and the breechblock. The breechblock is of the sliding wedge-type and is semi-automatic. It opens automatically on counter-recoil by the action of a lug under the left rear of the breechblock catching on the 'flexible cam as the gun returns to battery. As the breechblock opens, the empty shell case is extracted. The breechblock is then held open as the extractor catches in a machined groove of the block. When another round is rammed into the weapon the rim of the cartridge case trips the extractor and the release of the tension on a spring enclosed in a cylinder above the breechring closes the breechblock. The firing mechanism, of the percussion hammer type, is hinged to the lower part of the breechring and can be fired either by a lanyard or by pressure on the firing plunger located in the center of the elevating handwheel on the left side of the weapon. The firing mechanism is recocked on counter-recoil. b. Lower Carriage The trails are of welded steel construction and can be spread to a 60° angle for firing. At the rear of the trails are flat spades containing vertical openings for inserting steel plates. These stabilize the piece while firing. When travelling, the trails are fastened at the rear by a trail lock (loop and hook). The trails are fastened to the axle assembly by open, hollowed hinge pins. Hinge pin locks, consisting of plunger and lever, keep the trails in a closed position. The axle is eccentric in that the ends extend into a shock-absorbing assembly, held in a cylindrical housing. The eccentric axles are locked to the housing when firing and disengaged when the weapon is travelling. There is knee action effect when the weapon is being towed. The disk wheels are mounted on 8-ply, rubber tires, 3 inches by 5 inches. The tires are filled with an air-spaced material as there is no valve for inflating with air.

c. Top Carriage The top carriage consists of an irregular shaped steel base that pivots in traverse on the lower carriage. Trunnion seats are found to position the cradle of the weapon. The traversing and elevating gears are also found on the top carriage. The U-shaped cradle is attached to the top carriage at the trunnions. The elevating arc is attached to the rear of the cradle with a pin. The recoil mechanism is attached to the gun tube by the nut on the buffer cylinder. This cylinder moves with the tube in recoil and the piston rod remains stationary. The mechanism is composed of three spaced coil springs and the cylinder contains about four and one-half pints of glycerine and water. The elevating mechanism consists of a handwheel and two series of beveled gears and shafts extending to a worm and worm wheel. This in turn rotates the pinion which is housed to the rear and is part of the top carriage. The pinion contacts the elevating arc which is secured to the cradle and elevates the weapon. Both the elevating and traversing mechanisms are found on the left side of the piece. d. Sighting Equipment Sighting equipment on the gun examined is incomplete but the available parts indicate that a straight tube telescope is used for sighting. The sight bracket is mounted on the left and the range drum on the right of the piece. The window for the range drum is wide enough to allow the reading of three scales on the drum. It is assumed that the range drum has a range scale for the AP-HE projectile, the HE projectile, and a scale graduated into regular angular divisions. The telescope holder rides on a cam which is actuated by a shaft leading from the range drum across the top of the breechring. The cam has a regular curve but is mounted eccentrically to elevate or depress the sight, through the angle necessary for super elevation. e. Shield The shield is constructed of 4-mm steel armor and is fastened by four brackets to the top carriage. Openings in the shield allow for sighting. An apron of the same thickness of steel is attached to the lower carriage of the weapon and affords protection from small arms and shell fragments. f. Firing Program Five rounds of Japanese AP/HE ammunition and five rounds of Japanese HE ammunition were fired in the gun examined. The gun was star-gauged before firing. Form factors were estimated for both types of projectiles. Results of the tests were: (1) AP/HE Projectile Powder charge 14.00 oz Length of recoil 18 3/4 in (2) HE projectile Powder charge 14.00 oz Length of recoil 18 1/2 in Pressure gauges were placed in one round of each type of ammunition. All gauges but one were lost and this one, from an AP/HE round, indicated the pressure to be 20,600 pounds per square inch. *Generally known as Model 1 (1941) because designed in that year. |

| Advertisement |

![[Japanese 47-mm Antitank Gun]](pics/japanese-47mm-antitank-gun.jpg)